Reducing production costs – four effective ways

Reducing production costs is the decisive factor for a manufacturing company’s survival and profitability. The key to achieving this is not through drastic personnel cuts, but through smart, systemic optimization. By implementing an advanced production management system—such as Nexelem—leaders can gain control over the four critical areas of cost reduction: maximizing resource efficiency, eliminating waste, preventing expensive downtime, and optimizing workflows. Digitizing these processes allows for data-driven decisions that protect margins and ensure operational continuity without requiring heavy capital investment in new machinery.

It is possible to reduce production costs without drastic personnel changes. The outbreak of the pandemic led to a reduction or even complete suspension of production in many factories. The slowdown in manufacturing companies was therefore the most significant since the 2008 financial crisis. Longer delivery times for raw materials, fewer orders, and transportation difficulties, all related to the outbreak of war in Ukraine, are just some of the challenges facing Polish manufacturing companies. In times of crisis, reducing production costs is particularly important for many companies, as such measures enable them to maintain continuity of their operations.

Table of Contents:

What are production costs?

Production costs refer to the total expenses incurred by a company to manufacture a specific product. These expenses mainly include:

- purchase of raw materials,

- transport costs,

- property and utility charges,

- employee salaries.

Controlling and reducing production costs are among the basic tasks of every manufacturing company. These activities are not only the most effective way to survive in difficult times, but also a way to achieve higher profits.

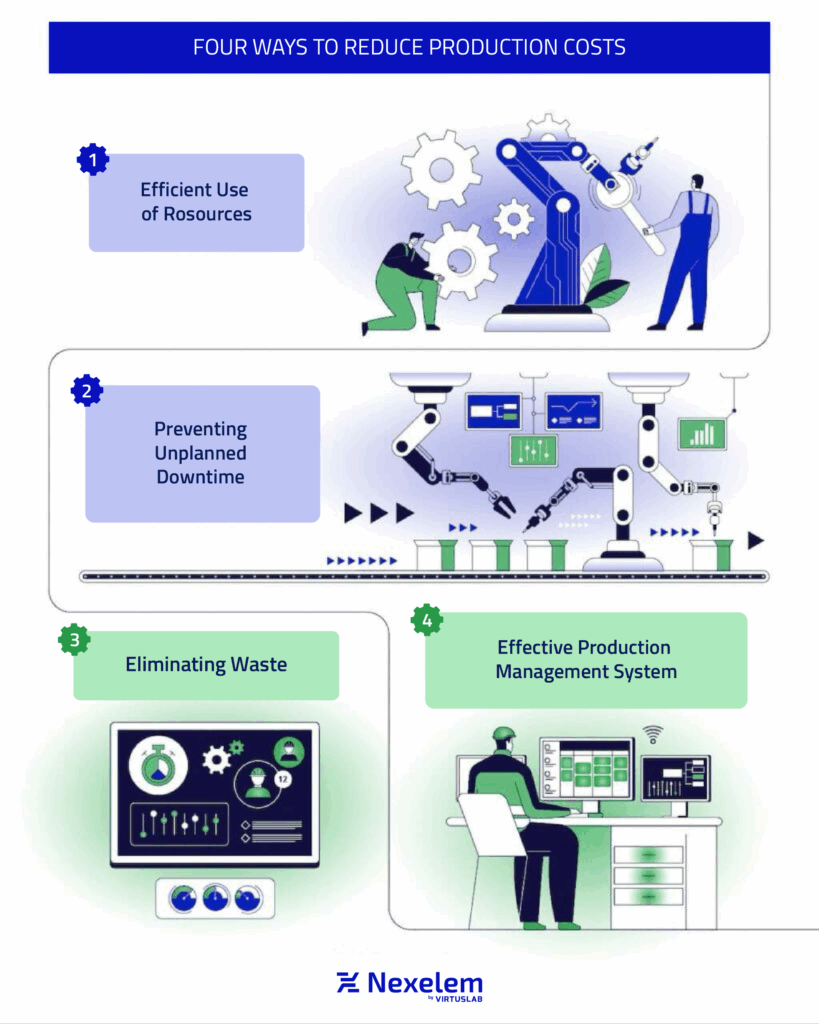

Four ways to reduce production costs

Cost reduction in a manufacturing company is often associated with cost-cutting. Of course, this is one way to reduce production costs; however, this approach is primarily focused on short-term goals. To achieve long-term results, fees must be reduced on a cyclical basis. How to reduce costs in a manufacturing company? There are several ways, including:

1. Efficient use of resources

Reducing production costs should focus on maximizing the use of available resources. Purchasing new machines is not always the only way to increase production efficiency. The situation is similar in the case of faulty machines. Repair may be a cheaper solution, and prompt maintenance response will save not only time but also money. Regular refurbishment extends the lifespan of equipment and reduces the need for costly replacements.

2. Preventing downtime

Every entrepreneur knows that production downtime is a very costly problem. The result is missed deadlines and customer dissatisfaction. The untapped potential of employees further exacerbates losses. It is not only a competent technical department or quick intervention by a service company that can effectively reduce the associated production costs. Measure downtime and micro-downtime using an MES system. Collect and analyze data to minimize the risk of future stoppages.

3. Elimination of waste

Waste is not only about the potential of raw materials themselves and how they are used. It is also vital to examine the amount of work and time needed to complete specific tasks. A practical solution would be to introduce an employee management system. This system enables us to track the time it takes employees to complete production orders. This knowledge also allows the effective management of workforce levels in the company and the adjustment of the employee incentive system according to the actual value they bring to the company.

4. Effective production management system

Very often, problems arising within a given process are responsible for generating excessive costs. Not only do they reduce efficiency, but they can also lead to various disruptions, ranging from quality issues to organizational problems. An efficient production management system is the basis for reducing costs in a manufacturing company, thanks to which we can more effectively manage:

- the production schedule,

- changeover times,

- employee productivity,

- production profitability.

Proper planning of the production order queue on each machine available in the plant is the most effective way to adjust resources, considering production time, available raw materials, and semi-finished products. It is one of the most effective methods of reducing production costs. How to reduce costs in a manufacturing company? This is currently one of the fundamental challenges facing Polish manufacturing companies. In this context, process optimization is also vital; therefore, we encourage you to read the article: Why Does a Manufacturing Company Need Material Requirements Planning Software?