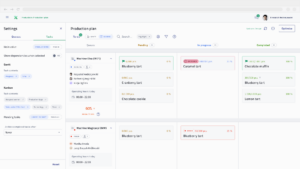

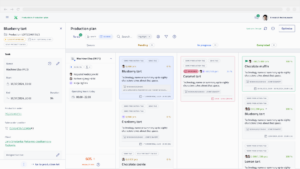

Kanban view

Kanban is a lean manufacturing tool. It is based on the visualisation of work using a special board. In its simplest form, the board is divided into three columns: To Do, In Progress and Done. This allows the production planning process to be clearly followed, increasing its efficiency and fluidity.