What is OEE?

OEE (Overall Equipment Effectiveness) is the overall efficiency of machinery used in production. It is a generally accepted standard for measuring the efficiency of a company’s production process. OEE is expressed as a percentage that strives for 100%. The higher the OEE value, the greater the production efficiency of a given production cell.

Table of contents:

- OEE as a manufacturing KPI – factors

- Why is understanding OEE so important?

- How to calculate OEE?

- Key factors for interpreting your index

- OEE monitoring in practice

- Which factors reduce OEE?

- How can you improve your production’s OEE?

OEE as a manufacturing KPI – factors

The OEE consists of the following factors:

- Quality of manufactured products

- Production efficiency

- Machine/workstation downtime

An OEE of 100% represents a perfectly efficient manufacturing where:

- All produced items meet quality standards

- Production is carried out with full availability of production resources (utilizing 100% of available resources, including machines)

- Planned production does not generate failures, changeovers, or other work stoppages

Why is it so important to understand OEE?

As a metric derived from three key performance indicators, OEE provides valuable insights into the state of production. As a production efficiency KPI, it can be calculated at various levels, from an entire production hall or organisation to a single production cell, workstation, or machine.

Effective management of this metric reduces production losses, including quality losses, and minimises downtime. This aligns with the Lean Manufacturing philosophy of reducing losses and increasing process efficiency.

OEE information enables us to identify areas for optimising the work of the entire company or a specific production cell/machine. Due to the three areas that make up the OEE (quality, performance, and availability), a change in its value alerts the production manager to a change in production quality. Because of the quality of the variables on which OEE depends, this metric provides information about bottlenecks in the process and thus about possible areas for production optimisation.

Once we know the bottlenecks in a given production cell, we can proceed with further process optimisation activities and use the same metric to assess the impact of implemented changes on the overall efficiency of equipment and tool utilisation.

How to calculate OEE?

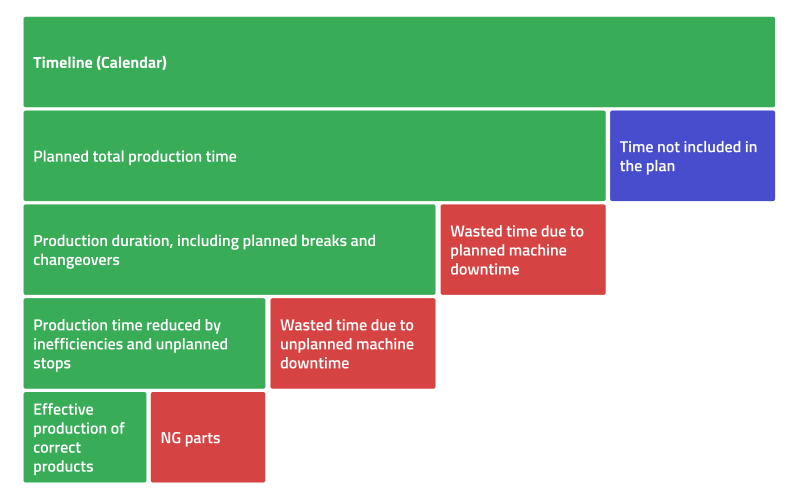

To calculate Overall Equipment Effectiveness (OEE), information about the condition of the organisation’s machines must first be collected.

This information will be as follows:

- Availability = (planned order time – changeover time) / planned order time

- Performance = (ideal production cycle time x quantity produced) / (planned order time – changeover time).

- Quality = number of good products/quantity produced.

These measures will enable you to calculate the overall equipment effectiveness index.

OEE = Availability x Performance x Quality.

Key factors for interpreting your index

When identifying the factors with the most significant impact on OEE, remember that there are three areas to consider:

- The number and quality of manufactured products

- Losses related to downtime and planned changeovers

- Losses in process efficiency are related to unplanned interruptions or slowdowns in the process.

OEE monitoring in practice

Monitoring this KPI is necessary to optimise it. However, it is crucial to do so correctly, as incorrect data collection methods can result in distorted data.

Firstly, it is worth asking what constitutes normal OEE. In reality, this depends on the industry and the product. In some sectors, a result above 85% is desired (for many managers, this is almost the gold standard), while in others, an OEE of 60% may be considered satisfactory. Experts from many industries, however, show that it is not only OEE that matters, but also other parameters that allow us to view processes in a broader context. It is always worth striving to continuously increase this metric, but never in isolation from other metrics.

OEE monitoring is carried out using dedicated software. This software is usually based on multiple data sources, primarily sensors and measuring devices that collect data from machines. Information can also be collected from production process management systems and modern vision systems. However, to obtain reliable data, these tools must be integrated.

Which factors reduce OEE?

We have finished implementing the system and have started receiving data on OEE in our company. However, it turns out that the KPI deviates from expectations. What should we do about it? Which factors could have contributed to the low OEE?

In practice, machine availability has a significant impact on OEE. This is primarily the case in situations involving high failure rates, micro-downtime and maintenance-related activities.

Incorrect production planning also causes reduced OEE. This can include delays in the delivery of raw materials, a slow response to unforeseen events, and MES software that does not meet the company’s needs. Our blog has more about implementing new MES software.

Other factors that lower OEE include:

- slow production cycles;

- defects in the process;

- activities related to setting up and adjusting machines;

- overly long planned breaks.

As you can see, there are many potential causes of problems. If OEE is low, you need to consider what is causing it. It may turn out that just a few minor changes will significantly improve your OEE.

How can you improve your production’s OEE?

In Lean Manufacturing, process optimisation is one of the methods used to improve the Overall Equipment Effectiveness indicator and reduce machine-related losses. More broadly, this KPI can be seen as an assessment of the holistic process of improving production and maintenance, as described by TPM (Total Productive Maintenance). The method of continuous production optimisation is defined in various ways, including:

- Lean Manufacturing

- Six Sigma

- Theory of Constraints

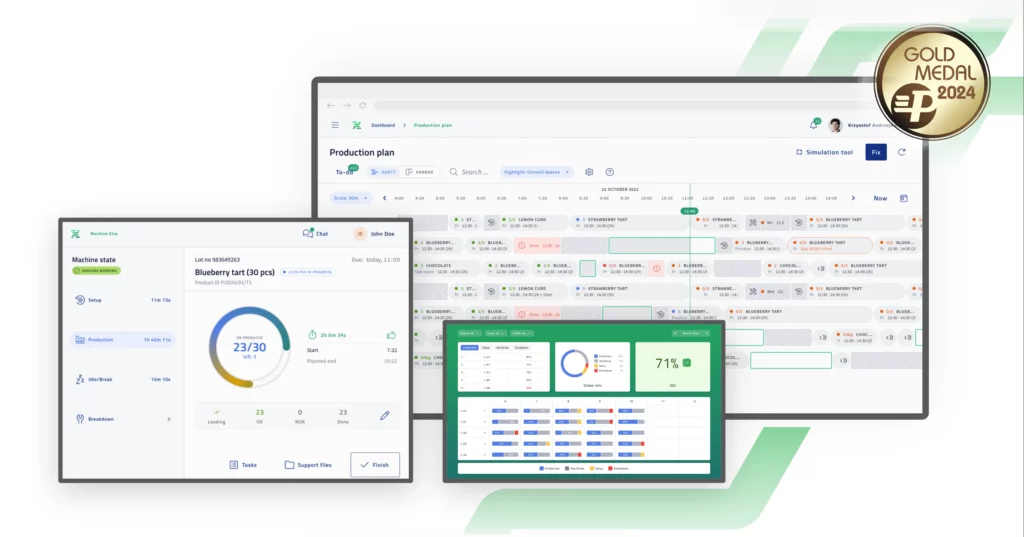

As an application based on Lean Manufacturing principles, Nexelem supports the reduction of losses and helps to maintain the continuous availability and efficiency of machines. Additionally, alongside our APS software, the MES system uses quality control (QA) modules and IIoT sensors to continually monitor product quality. Consequently, Nexelem is a ready-made solution for optimising the use of company resources, and the real-time calculation of the overall machine efficiency index within the MES module can enhance production efficiency.

F.A.Q.

About Nexelem

Nexelem is smart factory software with a modular architecture. It automates production planning, manufacturing execution and monitoring, taking OEE monitoring and optimisation to the next level. Contact us for an online presentation showcasing the capabilities of Nexelm.