Supply chain management – definition, challenges, and opportunities

High market competition, rapidly changing raw material costs, and the geopolitical situation. In such conditions, flexible and efficient supply chain management is a difficult task that requires excellent organization. How can it be done effectively? What are the other challenges in this area, and how can they be overcome? What are the most commonly used management methods, and which companies are they aimed at? Stay with us to learn how to manage your company’s supply chain best.

Table of contents:

- Supply chains in historical terms and their definition

- Logistics and supply chains

- What is supply chain management?

- The biggest challenges of supply chain management

- What are the benefits of effective supply chain management?

- The most popular supply chain management methods

- Selecting a supply chain management method

- Supply chain management – Summary

Supply chains in historical terms and their definition

Supply chains are obviously not a new phenomenon, as they have existed since ancient times, when the first commercial transactions took place. However, the term itself only appeared in the second half of the 20th century, when industrialization gained momentum and these processes became much more complex and multi-level.

So, how can a supply chain be defined? In practice, it is the process from placing an order for a specific product to settling the transaction. It therefore includes the stages of planning, implementation, and control of activities that connect the product’s source to its end customer. Today, however, it is a highly complex process subject to frequent fluctuations due to geopolitical and economic factors, as well as changing market needs.

Logistics and supply chains

It is also worth outlining what logistics are in this context. As it turns out, it is one of the elements of the supply chain, which includes activities such as storage, transport, and distribution of products. These terms should not be confused, as logistics management covers only part of the supply chain process.

What is supply chain management?

The concept of the supply chain is inextricably linked to its management, i.e., Supply Chain Management. The aim in this case is to properly coordinate the links in the supply chain to optimize it and increase the company’s efficiency. However, the challenges of today make coordination in this area difficult. Therefore, companies are increasingly turning to modern supply chain management systems to streamline processes and ensure competitiveness in the markets.

The biggest challenges of supply chain management

Supply chain management poses many challenges for entrepreneurs. It is essential to be aware of these challenges to counteract them more effectively and operate more efficiently. Here are the most important ones.

Firstly, these chains are currently very complex and subject to many changes, including personalization, which requires manufacturers to be much more flexible in their operations. However, a flexible approach to such complex processes is not straightforward and requires modern management.

Secondly, geopolitical and economic changes have a significant impact on supply chains, especially in manufacturing companies that use extracted raw materials. In this case, flexibility is again necessary to quickly reconfigure the supply chain and obtain materials from another source, ensuring products are delivered without delay. Of course, in this situation, proven supply chain and warehouse systems are also essential to manage raw materials more effectively.

Thirdly, companies have recently faced increased costs at every stage of the supply chain. Reducing these costs is often a matter of survival for a given entity, which is why optimizing expenses is so important in supply chain management.

Fourthly, entities must meet the needs of customers at subsequent links in the chain, who expect the highest possible transparency into processes. To make this possible, modern systems for collecting data at every stage are necessary, but in the most transparent form possible.

What are the benefits of effective supply chain management?

Knowing the challenges is one thing, as is being aware that they will always arise. However, it is worth focusing on the opportunities offered by effective supply chain management rather than stopping at optimization.

1. Lower costs

Reducing costs is one of the main ways to improve market competitiveness. Therefore, effective supply chain management is primarily about controlling expenses and checking which stages consume the most resources and how to counteract this. What can generate these costs in the supply chain? There are, of course, many examples, one of which is inefficient management of the supplier fleet and empty runs in the delivery process.

2. Greater process flexibility

As we mentioned, the challenges of supply chain management in today’s reality are variable. That is why flexibility in approach is so essential, so that, in the event of various problems and challenges (e.g., with the supply of production materials), they can be better addressed. The basis for increasing flexibility is the data provided on an ongoing basis by SCM management systems, which are offered by an increasing number of companies.

3. Greater productivity

Supply chain management is a very complex process. However, if it is properly optimized and streamlined, then you can expect an increase in productivity. Greater productivity usually means greater profits.

4. Better customer relations

Customers are absolutely key elements in supply chain management. They have a significant impact on its shape, as it is their needs – often growing, but also changing over time – that force the optimization of individual processes. However, thanks to more effective supply chain management, there is an opportunity to significantly improve customer relations and thereby enhance the entity’s competitiveness. The result? Higher profits, less susceptibility to customer loss, and greater market confidence.

The most popular supply chain management methods

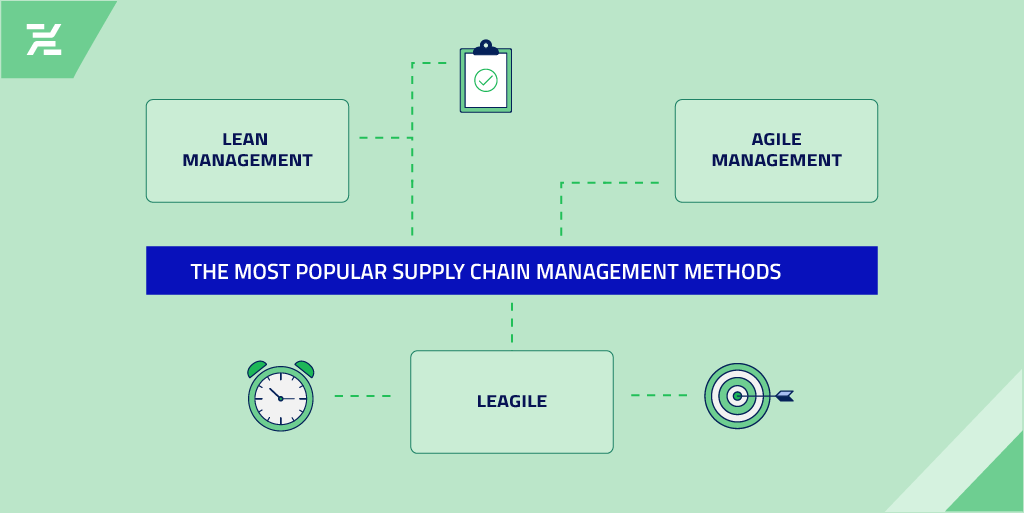

In the context of supply chain management, one method among many can be used. Choosing the right one is the key to success, and there are, of course, many factors to consider in this case. The most important of these are demand and product life cycle, although the market, which has undergone intense changes in recent years, is no less critical. Here are the most important techniques used in this area.

1. Lean Management

Lean Management in the context of supply chain management is a well-known and valued method. Its goal is to “streamline processes,” especially by reducing the costs of individual stages, so the end customer can enjoy the lowest possible price. When does this approach work best? Mainly for products with a long life cycle and when demand for them is predictable, as is the case in the automotive industry.

Our blog will also explain what Lean Manufacturing is and the benefits it offers.

2. Agile Management

Flexibility is a word that often appears in the context of supply chain management. It is therefore not surprising that Agile Management, or flexible management, is so popular. The goal here is to respond quickly to changing market needs to meet expectations. It is most often used for products with a short life cycle and manufactured in many variants, but in small quantities. This approach is used, for example, in the fashion market.

3. Leagile

A lesser-known but equally interesting method is Leagile, which combines Lean and Agile approaches. It is the most holistic concept, combining the advantages of each approach and thus proving very effective in the current economic reality. HP is a company that uses this approach. In the case of printers, their manufacturing process is based on aggregated demand, in accordance with the Lean method. However, they are later adapted to different markets when orders are received, i.e., in accordance with the Agile approach.

Selecting a supply chain management method

Choosing the correct method is an essential step on the road to success. But how do you choose the right one? In addition to demand and life cycle, it is necessary to consider the company’s experience, how it operates at its current business stage, and whether it has modern IT technologies that provide relevant data from each stage of the supply chain. Unfortunately, without such systems, effective supply chain management is practically impossible today. However, they must be perfectly tailored to the company’s needs and the specifics of its operations.

Supply chain management – Summary

Supply chain management requires mastering very complex processes. Without efficient organization, problems with the flow of goods can negatively affect trade relations and disrupt the business’s economics.

Are you looking for solutions to optimize your company’s supply chain management? Contact us to streamline your operations and increase profits.

F.A.Q.

What is a supply chain?

A supply chain is a comprehensive process from placing an order for a product to settling the transaction. It includes the stages of planning, implementation, and control of activities, connecting the product source to the target customer.

What is the role of logistics in the supply chain?

Logistics includes activities related to the storage, transportation, and distribution of products within supply chains, making it a key element of supply chains.

What is supply chain management?

Supply chain management is the coordination of processes to optimize the supply chain, increase business efficiency, and adapt to changing market and geopolitical conditions.

What are the benefits of effective supply chain management?

Effective supply chain management results in lower costs, greater flexibility, higher productivity, and better customer relationships, which, in turn, translate into greater market competitiveness.

What are the most popular methods of supply chain management?

Among the most popular methods are Lean Management, Agile Management, and Leagile, each with its own application depending on the specifics of the product, its life cycle, and the changing market.