SuperAI 2025: How AI Meets Industry 4.0 in the Era of Humanoids

The SuperAI 2025 conference in Singapore highlighted the convergence of AI and Industry 4.0, emphasizing the rise of specialized humanoid robots for industrial tasks. This new era of “Embodied AI” and spatial computing will see task-focused robots working alongside humans, leveraging digital twins of factories for enhanced navigation and collaboration. As these smart factories become more connected, the article underscores the critical importance of AI-powered cybersecurity to defend against sophisticated, AI-generated threats.

I attended SuperAI Singapore 2025 (June 18-19) and left energized about how AI can reshape manufacturing. The conference drew over 7000 innovators in AI, robotics, healthcare, manufacturing and more.

At Nexelem, we’re developing our system in close collaboration with the manufacturing industry, while also looking beyond the horizon, so that our approach helps set the direction, not just follow it.

Over two days at Marina Bay Sands, the program featured three stages, hackathons, and startup contests, with a heavy focus on automation and real-world AI. A quick survey the organizers shared had already flagged “Embodied AI (e.g. robotics, advanced manufacturing)” as one of the top trends poised to make an impact. It felt spot-on: sessions like “Robotics Renaissance: AI’s Role in Automating the Physical World” underscored that Industry 4.0 is front and center.

Table of contents:

- What’s the sign of an AI revolution in the Industry 4.0 concept?

- AI in the physical world

- The physical world accessible to AI

- Smart Factory and Security in the Era of AI

- Last but not least

What’s the sign of an AI revolution in the Industry 4.0 concept?

Are there any? What about smart factories? Are they smarter with AI implementation?

— So many questions!

For me, Industry 4.0 means a smart, connected manufacturing environment powered by data. It’s about linking machines, sensors, and data so factories can make decisions independently (of course, at some level of autonomy) in real time. In essence, smart factories turn data into useful information to let humans make better business decisions.

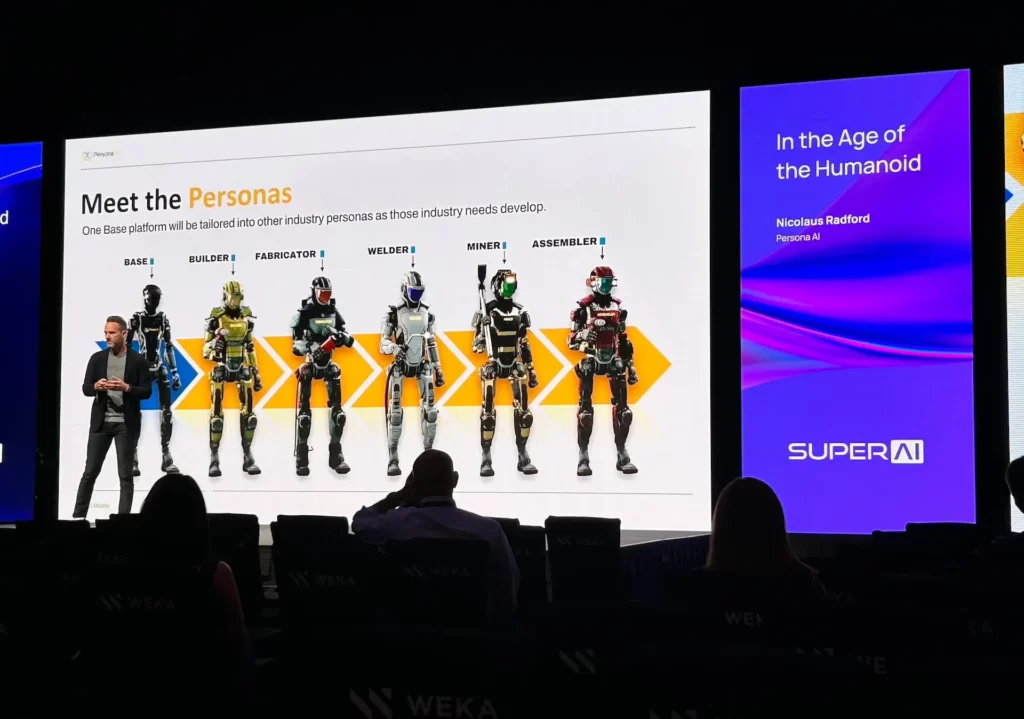

Walking the expo halls, I saw many demos of interesting tech. Also, some keynotes caught my attention. For example, Persona AI showed off its vision of robots as industrial workers. I sat on a “Physical AI” panel where Persona’s CEO Nicolaus Radford and others explained that humanoid machines will first be specialized tools, not general-purpose bots.

In practice, Persona lets customers “pick your persona” for each robot. They literally offer robots configured as Builder, Welder, Fabricator, Assembler, and even Miner – each one a humanoid tuned to a different skilled trade. For instance, the Builder persona “executes construction and structural assembly tasks safely”, while the Welder persona “delivers welding in hazardous environments”. Persona’s roles include:

- Builder: Executes construction and assembly tasks safely.

- Welder: Performs welding in changing or hazardous conditions.

- Fabricator: Cuts, shapes, and finishes metalwork under tough conditions.

- Assembler: Performs assembly tasks in hard conditions.

These examples showed me that, in a modern factory, we’re moving toward fleets of task-focused robots. Radford emphasized that early humanoid robots won’t try to do everything – instead, they’ll be “segmented into different Personas” for welding, assembling, etc. In fact, Persona AI already inked a deal with Korea’s HD Hyundai to deploy humanoid welding robots in shipyards. This confirmed my own view: soon we’ll see specialized robot welders, builders, and fabricators working side-by-side with humans. These robots extend Industry 4.0 by offloading dangerous or tedious labor, much as I understand future humanoid workers who use a working environment and tools designed by humans for humans.

Physical AI: The New Age of Intelligent Robotics – SuperAI Singapore 2025

Source: SuperAI’s YT Channel

AI in the physical world

Another big theme was spatial computing – essentially letting AI perceive and navigate the physical world. Auki Labs stole the show with demos of “Physical AI” on the exhibit floor. Their booth showcased augmented reality and mapping tech that blur the line between digital intelligence and shop floors.

As one poster put it, they envision “AI entering the physical world enabled by spatial computing”. For example, Auki demonstrated Gotu, an app-free indoor navigation system. With AR glasses or phones, Gotu let me see waypoints in the hall and guide me to booths without any installed antennas or other RF equipment.

— Imagine a worker wearing smart glasses in a warehouse, following AR arrows to the correct rack or machine – a clear Industry 4.0 use case.

Auki also showed Cactus, a spatial AI platform for retail, which in factories could translate to real-time analytics of machine positions and inventory layout. These demos brought home how factories will soon have “digital twins” and shared maps enabling robots and humans to coordinate in real space.

On stage, Auki’s CEO, Nils Pihl, took these ideas even further. In his keynote titled “DePIN: The Decentralized Nervous System of Physical AI” he argued that “the next x10 leap in global productivity will come from AI agents operating in physical space”.

In other words, Nils predicts factories will only see huge gains if our machines share spatial data in real time. He made the analogy that old tools like GPS won’t cut it; instead, we need a new infrastructure. Indeed, Auki describes their network as a “posemesh” – “an external and collaborative sense of space that machines and AI can use to understand the physical world”.

The physical world accessible to AI

To me, that means the factory of the future is like a connected 3D web: robots, drones, and sensors all post and read maps of the factory floor. This allows things like multi-robot coordination and live AR overlays for maintenance. As Nils quipped after his talk, “the convergence of AI and spatial computing is not just inevitable, it’s already happening”.

And he’s right! Many manufacturing plants are already putting this into practice by using Real-Time Locating Systems (RTLS) like Sewio. RTLS enables creating a live digital copy of the shop floor that mirrors what’s happening in real time. The location data doesn’t just sit in dashboards; it feeds other systems, machines, and even robots. This allows them to react instantly to actual conditions and run simulations that help plan changes.

Of course, during a time when many factories struggle with production scheduling and efficient material requirements planning without proper APS software, all these may sound like exaggerations. They certainly may be. However, if we want to have better, more efficient smart factories of the future, we have to think big, provide humans with better tools, and enable more time for self-development.

Nils Pihl – DePIN: The Decentralized Nervous System of Physical AI

Source: SuperAI’s YT Channel

Smart Factory and Security in the Era of AI

Beyond robotics, the conference reminded me of another Industry 4.0 challenge: security. Modern factories run on networks and devices, making them targets. I saw panels on AI-driven cyber defense and heard warnings about vulnerabilities. The stats are scary: a recent analysis found that “in 2023, the manufacturing sector experienced the highest share of cyberattacks among leading industries” – up 42% from the prior year. 65% of factories got hit by ransomware, and IoT malware has spiked by over 400%. In plain terms, as we connect more machines and use AI to manage them, hackers have new ways to get in. Worse, cybercriminals are fighting fire with fire: they’re now using generative AI to write novel malware and probe for weak spots.

This means my friends, factory workers, need AI to help defend the plant as much as it helps run it. Securing networks, encrypting sensor data, and training staff all become urgent priorities alongside adding robots. The reality is that Industry 4.0 doesn’t just bring efficiency; it brings new risks that manufacturers must handle.

Join me and watch the entire debate called Cybersecurity Redefined: Digital Defense in the Age of AI

Source: SuperAI’s YT Channel

Looking ahead, I feel optimistic. SuperAI 2025 showed concrete glimpses of tomorrow’s smart factory. We saw that humanoid robots will arrive in factories in specialized roles, backed by modular platforms. We saw that spatial computing and AR are poised to weave AI into every machine, letting robots and humans share a common view of the workspace. We also saw that the industry is acutely aware of cybersecurity; the factories of the future will have to guard themselves against AI-powered hackers.

Last but not least

Industry 4.0 is here, and the new industrial revolution is approaching. In this revolution, AI will have access to the physical world in the form of humanoid robots that use tools designed for humans.

The future factory will be a place where smart machines, sensor networks, and augmented humans work together in harmony.

It’s up to us in the industry to responsibly shape that future, ensuring that our intelligent factories boost productivity while staying safe for their most precious assets: us humans.

Are you a prodution manager?

Nexelem is a next-generation production management suite that helps you streamline factory operations, execute production, and automate scheduling. It is people-centric and supports the Industry 4.0 concept.

F.A.Q. concerning SuperAI 2025

Video memories from SuperAI 2025.