Handling Rush Orders: How to Reschedule Production Without Chaos

It is 2:00 PM on a Tuesday. The production floor is humming, the weekly schedule is locked in, and your OTIF (On-Time In-Full) metrics look promising. Then, the phone rings. It is your sales director. A key client needs a massive order delivered by Friday, or they will take their business elsewhere.

In many manufacturing companies, this moment triggers immediate panic. The “firefighting” mode begins: planners scramble to find capacity, machine operators are abruptly told to switch setups, and materials are pulled from other jobs. While the rush order might get done, the collateral damage is often severe. Other orders are delayed, overtime costs skyrocket, and the factory floor descends into confusion.

This scenario is common, but the chaos is not mandatory. Rush orders are an inevitable part of modern manufacturing, but they do not have to break your production process. With the right production rescheduling strategies and digital tools, you can pivot quickly without disrupting your factory’s entire ecosystem.

Table of Contents

- The High Cost of Static Planning

- Understanding Production Rescheduling Strategies

- The Power of Predictive-Reactive Scheduling

- Nervousness-Aware Rescheduling: Stability vs. Agility

- How Nexelem Enables Dynamic Rescheduling

- A Step-by-Step Workflow for Handling a Rush Order

- Conclusion: Turn Agility into a Competitive Advantage

The High Cost of Static Planning

The traditional approach to production planning is often too rigid. Schedules are created in Excel spreadsheets or legacy ERPs days or weeks in advance. These static plans assume a perfect world where machines don’t break, materials arrive on time, and customers never change their minds.

When a rush order hits a static plan, the manual effort required to adjust it is overwhelming. A planner must mentally calculate the ripple effect of inserting a new job:

- Which current job gets bumped?

- Do we have the raw materials available right now?

- Will this require an extra changeover or cleaning cycle?

- How does this affect the delivery dates of the five other orders in the queue?

Without visibility, planners often make these decisions based on gut feeling rather than data. The result is usually a successful rush order but a disastrous drop in overall plant efficiency and profitability.

To solve this, manufacturers must move from static planning to dynamic rescheduling.

Understanding Production Rescheduling Strategies

Production rescheduling is the process of updating an existing production schedule in response to disruptions or changes, such as new high-priority orders, machine failures, or material shortages.

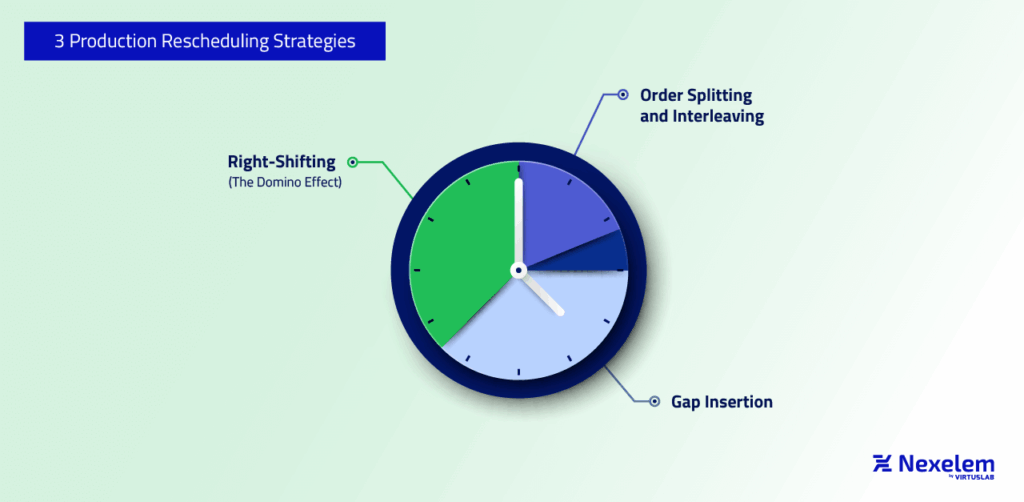

To handle rush orders effectively, you cannot simply “squeeze it in.” You need specific production rescheduling strategies that minimize the negative impact on the rest of the queue. Here are the three most effective approaches:

1. Right-Shifting (The Domino Effect)

This is the simplest form of rescheduling. You insert the rush order into the timeline and push all subsequent jobs forward (to the right on the timeline).

- Pros: It preserves the original optimization’s sequence.

- Cons: It blindly delays every order after insertion, jeopardizing OTIF scores for multiple clients.

2. Gap Insertion

If your schedule is not running at 100% capacity, you might have gaps between shifts or maintenance windows. Smart rescheduling looks for these idle pockets to fit the rush order without moving other committed jobs. This often requires a granular view of machine availability that spreadsheets cannot provide.

3. Order Splitting and Interleaving

Sometimes, the rush order is too large to fit into a single gap. A sophisticated strategy involves splitting the rush order into smaller batches and interleaving them between existing jobs. This keeps the high-priority client happy by delivering a partial shipment immediately while maintaining momentum on standard orders.

The Power of Predictive-Reactive Scheduling

Modern manufacturing requires a hybrid approach known as predictive-reactive scheduling.

- Predictive: This is your baseline plan. You generate a schedule for the week based on known demand, optimizing for efficiency and minimal changeovers.

- Reactive: This is your ability to adjust when reality hits. When a rush order arrives, the system regenerates the schedule from that moment forward.

Predictive-reactive scheduling allows you to maintain a stable long-term vision while possessing the agility to handle short-term crises. It isn’t about throwing away the plan; it is about adapting the plan intelligently.

This approach relies heavily on real-time data. If you don’t know the exact status of every machine and order on the floor right now, you cannot effectively react. You need a system that serves as a digital twin of your production floor, allowing you to test changes before executing them.

Nervousness-Aware Rescheduling: Stability vs. Agility

One of the most significant risks in handling rush orders is a phenomenon called “schedule nervousness.”

Imagine you change the schedule at 2:00 PM. Then, the material is delayed until 3:00 PM, so you change it again. Then another rush order comes in at 4:00 PM. If the schedule changes too frequently, the shop floor operators lose trust in the plan. They stop preparing for the next job because they assume it will change anyway. This leads to increased idle time and frustration.

Nervousness-aware rescheduling is a sophisticated algorithmic approach that balances the need for change with the cost of instability.

- It asks: “Is inserting this rush order worth the disruption of changing the setup on Machine A?”

- It creates a “frozen zone” in the immediate future (e.g., the next 4 hours) where no changes are allowed, ensuring operators have stability.

- It optimizes the schedule beyond the frozen zone to accommodate the new demand.

By implementing nervousness-aware rescheduling, you ensure that your office agility doesn’t translate into confusion on the factory floor.

How Nexelem Enables Dynamic Rescheduling

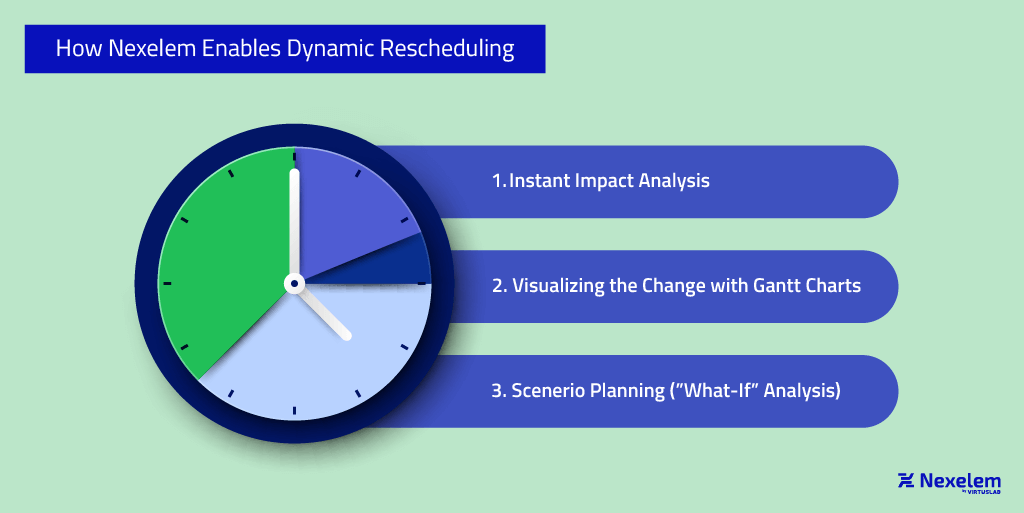

Theory is functional, but execution requires tools. This is where Nexelem’s APS (Advanced Planning and Scheduling) Software bridges the gap between chaos and control.

Nexelem moves beyond simple lists and dates. It uses advanced algorithms to visualize your production capacity in real-time. Here is how it transforms the rush order process:

1. Instant Impact Analysis

When a rush order request comes in, you don’t have to guess if you can do it. You can drop the order into Nexelem as a simulation. The system immediately calculates:

- The earliest possible completion date.

- Which other orders will be delayed?

- Required material availability (checking against your MRP System data).

2. Visualizing the Change with Gantt Charts

Text-based lists make bottlenecks hard to see. The Gantt Chart View in Nexelem shows where the rush order fits.

You can drag and drop the new order onto a machine’s timeline. The system automatically highlights conflicts, such as overlapping jobs or missing maintenance windows. Visual management empowers planners to identify optimization opportunities that algorithms might miss, such as combining similar paint colors to reduce setup time.

3. Scenario Planning (“What-If” Analysis)

Before you commit to the client, you can run multiple “What-If” scenarios in Nexelem.

- Scenario A: We run the rush order on the main line (fastest, but it disrupts 3 other jobs).

- Scenario B: We split the order across two auxiliary machines (slower, but preserves the main schedule).

- Scenario C: We authorize overtime for the weekend.

Dynamic rescheduling empowers you to present management with costed options rather than just problems. You can say, “We can accept this rush order, but it will cost $X in overtime or delay Client Y by 24 hours. Which do you prefer?”

A Step-by-Step Workflow for Handling a Rush Order

To move from chaos to clarity, adopt this workflow when the following urgent request comes in:

- Verify Material Availability: Before rescheduling anything, ensure you have the raw materials on hand. There is no point in disrupting the schedule for an order you cannot finish. (See how Material Requirements Planning integrates here).

- Define the Constraints: Is the deadline negotiable? Is the quantity fixed?

- Simulate in APS: Use Nexelem to insert the order into the schedule tentatively. Look for the “least disruption” path using predictive-reactive logic.

- Communicate the Impact: If the simulation shows that a key account’s order will be late, communicate this internally immediately.

- Execute and Monitor: Once the plan is approved, push the update to the shop floor. Use real-time tracking to ensure the rush order progresses as planned without causing the “nervousness” ripple effect.

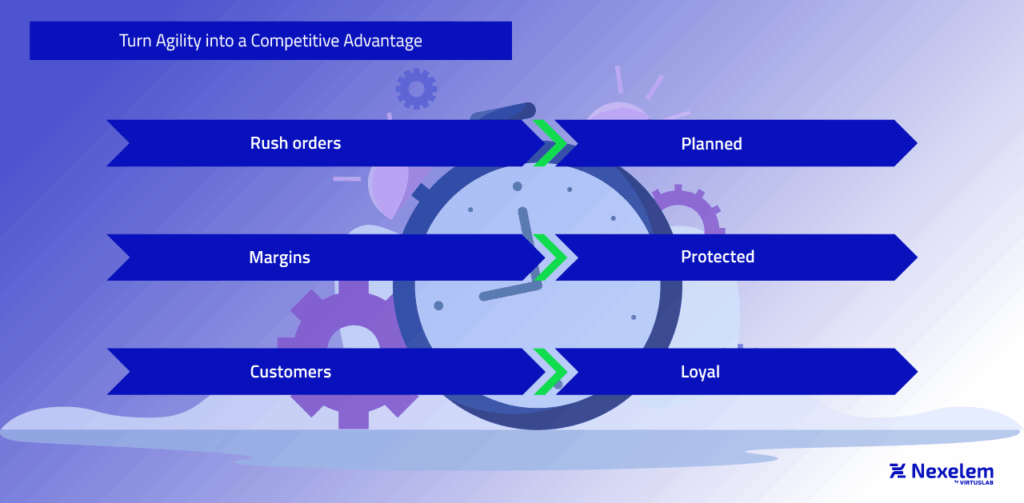

Conclusion: Turn Agility into a Competitive Advantage

In a competitive market, the ability to say “yes” to a rush order without destroying your margins is a superpower. Customers value reliability, but they pay a premium for flexibility.

If your current process for handling rush orders involves shouting across the factory floor or frantic Excel formulas, it is time to upgrade. Dynamic rescheduling transforms the unexpected into the routine. It allows you to protect your production costs while maximizing service levels.

Stop fearing the phone call. Start planning for it.

Ready to see how your factory can handle the unexpected? Explore Nexelem’s APS Software and take control with our interactive Gantt Chart View.