Gemba Walk: Why and How to Visit the Production Hall?

The Gemba Walk is a critical management practice rooted in Lean philosophy that bridges the gap between how managers think production works and how it actually works. It involves decision-makers leaving their offices to visit “the place where things happen” (the production floor) to observe processes, engage with employees, and identify areas for improvement based on reality rather than assumptions. To be effective, a Gemba Walk must be distinct from a compliance audit or a “raid.” It requires a structured approach: planning the visit, communicating with the team, recording observations without immediate judgment, and analyzing the data to implement meaningful changes—often supported by digital tools like MES systems to quantify the findings.

Gemba is a philosophy increasingly used by managers supervising activities related to the production process. It can also be successfully applied in companies of any type. It aims to bring people closer to the places where products and services are created. It allows for regular checks on what can be improved in the process. This is one of the core reasons why organizations ask what is a gemba walk and how it supports continuous improvement. Let’s take a look at what exactly this approach involves and how to utilize it in day-to-day operations.

Table of contents

- What is Gemba, and where did this approach come from?

- What is Gemba Walk?

- Gemba in the Lean Management approach

- Gemba Walks and the Kaizen approach

- The 7 principles of Gemba Walk in practice

- What must NOT be Gemba Walking?

What is Gemba, and where did this approach come from?

Gemba is a Japanese word meaning “the place where things happen.” So, when asking what does gemba mean, it refers to the place where transformative processes take place, where a product or service is perfected and acquires its most essential characteristics. In other words, this explains what is gemba in manufacturing and why it plays such a crucial role in operational excellence. In the case of a manufacturing company, this would primarily be the assembly line, where the product takes on its actual and final form.

This approach, therefore, involves regularly visiting such a place, which forms the foundation of gemba in manufacturing practices, allowing for direct observation and control over the process (but without blaming the employees), with the possibility of finding ways to optimize the process later on. However, for this to be possible, such activities should be performed in a specific manner.

What is Gemba Walk?

Gemba Walk, in accordance with the above definition, means walking around the place where key events for the company’s operations take place. So, when managers ask what is a gemba walk in manufacturing, the answer lies in structured, purposeful observation at the source. Such a walk provides direct contact with the process, as well as with the people responsible for it. A manager or supervisor who practices Gemba Walk focuses not only on the process, but also on people, building relationships and trust with them. This clearly highlights the true purpose of gemba walk: learning, not controlling. The key is therefore to ask the right questions, although this must be done in a non-intrusive manner, without a controlling approach or mistreatment.

Gemba in the Lean Management approach

Lean management requires, above all, the collection of all necessary data to optimize processes. The Gemba Walk concept fits perfectly into this trend. It enables managers to gain closer insight into the production process and access the most critical information about it. In practice, this shows what gemba walk in manufacturing looks like when Lean principles are applied correctly. It also allows them to learn about the company’s current problems first-hand, i.e., directly from the employees who are involved in the process. Without such observation and conversation, implementing changes becomes almost like walking blindfolded. That is why Gemba Walking is such a common approach in Lean Management, which must be based on facts, not guesswork.

Gemba Walks and the Kaizen approach

Kaizen is a method of continuous improvement, and the Gemba philosophy is also part of it. In this context, it becomes clear what are gemba walks: regular, structured opportunities to identify incremental improvements. In this case, Gemba is simply one of the tools used in Kaizen. Such walks promote the involvement of everyone. In fact, they are a way for senior management to meet with production line workers, who often have the most valuable insights into the process and the changes that are needed.

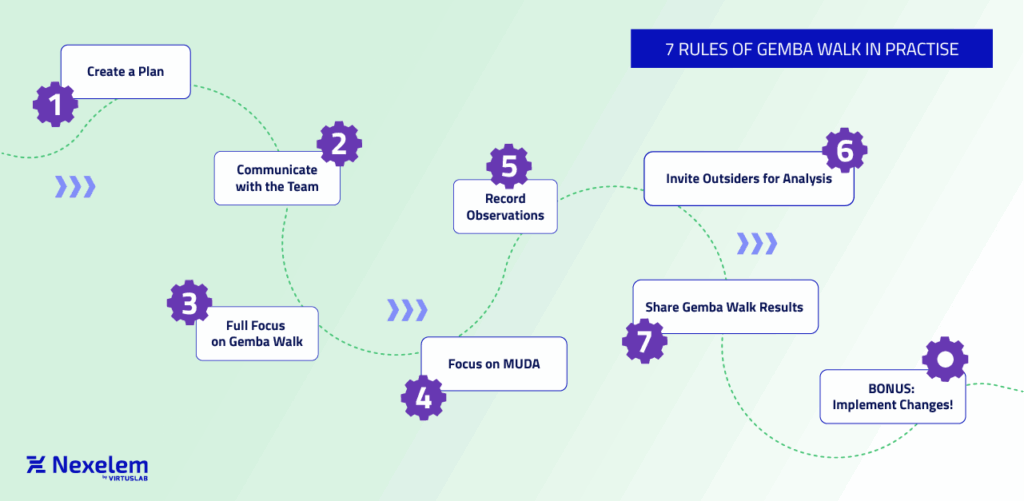

The 7 principles of Gemba Walk in practice

An inadequate understanding of this method can cause it to turn into a search for culprits rather than a regularly performed process designed to benefit the company and build a more engaged team of employees. Therefore, to understand how to plan an efficient gemba walk, it is essential to follow proven principles that have been developed based on many years of experience with this technique.

1. Create a plan

During such a walk, the manager must always keep their eyes wide open and be open to whatever they encounter. Nevertheless, it is worth making a rough plan for the Gemba Walk, which is a key element of how to plan an efficient gemba walk, i.e., indicating specific areas that will be checked.

2. Communicate with the team

Employees definitely do not like being stared at while performing their daily tasks. Therefore, it is worth communicating to them what Gemba Walk is and why it is being done. This reinforces trust and clarifies the real purpose of gemba walk. Otherwise, you may encounter suspicion from employees, and they will be reluctant to share their experiences.

3. Full focus on Gemba Walk

Unfortunately, Gemba Walking often turns into a session of answering phone calls, which means that attention is not entirely focused on the process. This is obviously the wrong approach, and such walks should be treated as seriously as meetings with contractors. It is therefore important to be aware of their importance for the company, which will allow you to focus on the present.

4. Focus on MUDA

MUDA refers to losses in the process, which, according to the Lean approach, should be minimized. Therefore, during a Gemba Walk, it is worth focusing on those operations that are not the most effective and that can be improved for the benefit of the company. What does this mean in a manufacturing company? First and foremost, there are several key issues: overproduction, excessive stockpiling, unnecessary waiting, unnecessary movement or transport, and underutilization of employee capabilities.

5. Recording observations

The primary purpose of a Gemba Walk is observation, without jumping to conclusions. This reinforces why what is a gemba walk is fundamentally different from audits or inspections. That is why it is a good idea to have a notebook with you to record your initial observations without interpreting them immediately. The time for interpretation comes a little later.

6. Inviting someone not involved in the process to analyze

Over time, the process can become somewhat repetitive and less beneficial than it was at the beginning. That is why it is a good idea to occasionally invite someone from another department who is not involved in production to join you on such a walk. The benefit of this approach is a fresh perspective, which may allow you to draw new conclusions.

7. Communicating the results of Gemba Walk

It is also important in this approach that Gemba Walking does not go unnoticed. It is worth sharing your conclusions with other team members, as well as with those directly involved, i.e., employees. This will allow the latter to see that such walks have a specific purpose. They will also understand that their role is not to catch mistakes, but to detect process problems.

Bonus: Implement changes

Gemba Walking is designed to help identify areas for improvement. So, if such areas are identified, it is essential to plan how to change them. This closes the loop of an effective gemba walk in manufacturing, turning observations into action. Of course, not all of them can be implemented immediately and with little effort. It is therefore best to approach the process in small steps, which is also in line with the Lean Management approach, especially the Kaizen philosophy.

Is production in your company excessively costly? Find out what a well-planned reduction in production costs should look like so that it does not lead to a decrease in product quality.

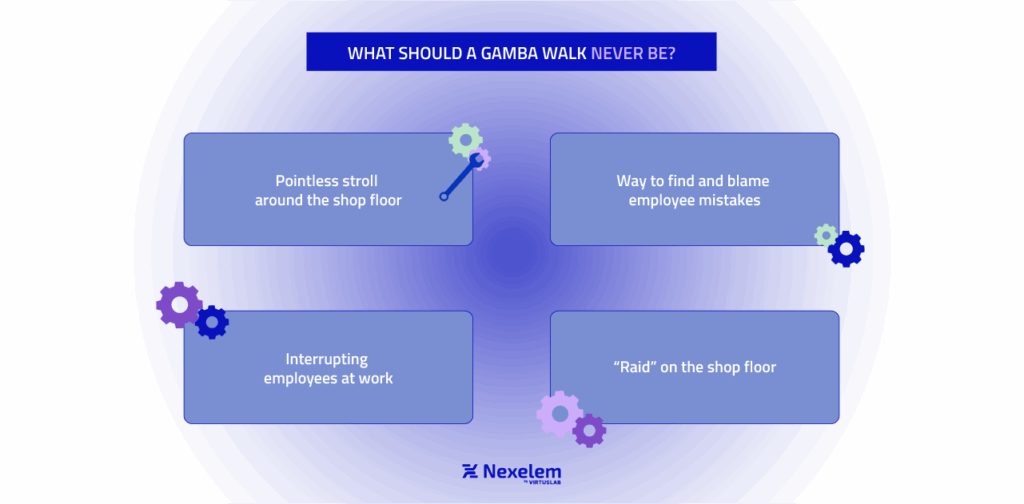

What must NOT be Gemba Walking?

Sometimes, Gemba Walking is mistakenly understood as a pointless walk around the production hall. In such cases, it is carried out only to show employees that their manager is involved in the process. However, this should not be the case, as pointless and frequent walks around the factory can be perceived negatively.

The walk should not be an opportunity to identify mistakes or blame employees for causing them. If Gemba Walking is treated in this way, it will be received with reluctance and may reduce trust in management.

Another mistake is to disturb employees while they are performing their tasks. Of course, there is nothing to prevent you from asking them for details about their tasks at this time. However, this cannot be done in such a way that it disrupts the daily schedule and causes delays in the production cycle.

An additional mistake is approaching Gemba Walking as if it were a raid on the production hall. It is worth ensuring that not too many people participate, ideally a few to a dozen or so high-level employees. Such an approach will bring a sense of control, which employees never welcome.

As you can see, Gemba Walk is not just a concept, but a practical answer to the question of what are gemba walks and why they matter in modern operations. It makes processes clearer to senior management, which can result in better, more meaningful changes.

The MES production management system along with APS software are one of the ways to optimize your company’s operations. Check out what we can offer you in this area.

F.A.Q. about the Gemba Walk

About Nexelem

Nexelem is a flexible, modular system that streamlines production management and optimizes operations. It was developed by VirtusLab Ltd., a company supporting global manufacturers since 2010. VirtusLab employs over 400 IT specialists who build software and digital tools focused on helping production companies achieve more, using fewer resources, with a lower environmental impact.

Discover how our solution works in your environment.