Finite vs. Infinite Capacity Planning: Which Approach Fits Your Factory?

Every production planner knows the feeling of “Schedule Shock.” The ERP system runs overnight and, it claims, generates a perfect schedule for the week. The screen says everything is green. But when you walk onto the shop floor with the printout, the foreman laughs.

“We can’t run Order A and Order B at the same time,” he points out. “They both need the 5-axis mill, and we only have one.”

This disconnect between the digital plan and physical reality is the most common friction point in manufacturing management. It stems from a fundamental difference in how software calculates time and resources: the battle between infinite-capacity and finite-capacity planning.

For many manufacturers, the reliance on basic tools creates a cycle of constant firefighting. Understanding the distinction between infinite and finite-capacity planning is not just an academic exercise; it is the prerequisite for moving from chaotic “best effort” production to reliable, profitable execution.

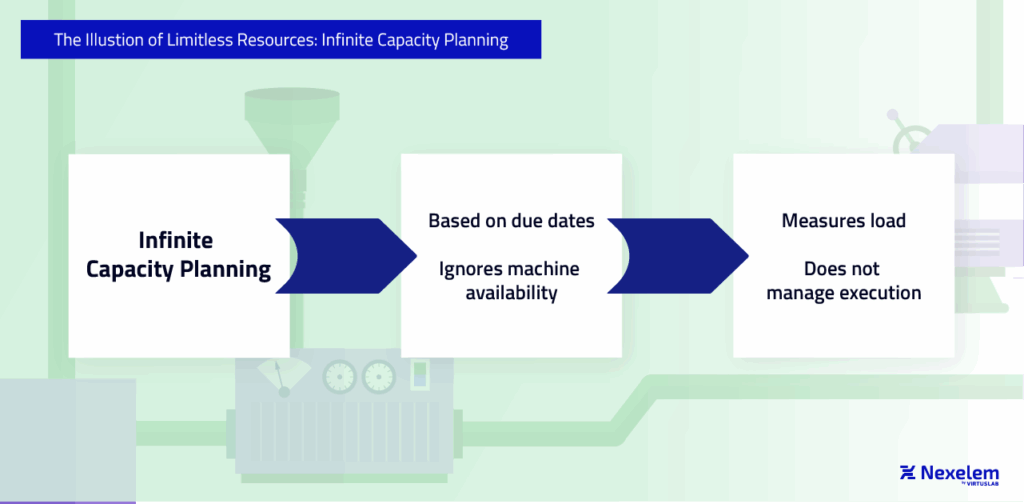

The Illusion of Limitless Resources: Infinite Capacity Planning

To understand why schedules fail, we must first understand the default logic of most traditional systems. MRP systems (Material Requirements Planning) were initially designed in the 1960s and 70s when computing power was expensive. To save processing power, they made a massive assumption: capacity is unlimited.

Infinite capacity planning schedules based solely on the customer’s due date and the product’s theoretical lead time. It ignores the current load on the shop floor.

How Backward Scheduling Works

Infinite planning typically uses “Backward Scheduling.” It starts at the due date (e.g., Friday) and subtracts the production time (e.g., 2 days) to tell you that you must start on Wednesday.

The flaw in this logic is that it does not check if the machine is actually free on Wednesday. If you have five orders due on Friday and each requires 2 days of production on the same machine, an infinite-capacity plan will schedule all five to start on Wednesday simultaneously.

The primary role of infinite capacity planning is to identify load, not to schedule execution. It is a bucket-filling exercise. It tells you, “To meet these deadlines, you need 100 hours of capacity this week.” It does not care that your factory only operates for 80 hours a week.

- When is it useful? Infinite planning is excellent for long-term strategic planning. It helps C-level executives decide whether to purchase new equipment or hire a second shift next quarter.

- When does it fail? It fails the moment you try to use it for daily execution. Giving an infinite schedule to a shop floor manager is asking them to solve a mathematical impossibility in their head.

The Reality of Constraints: Finite Capacity Planning

Limits define the shop floor. You have a specific number of machines, a specific number of skilled operators, and limited auxiliary tools. Finite capacity planning is the computational approach that respects these hard limits.

Finite capacity planning and scheduling algorithms do not just ask “When is it due?”; they ask “When is the resource available?”

The Logic of Forward Scheduling

Finite planning typically utilizes “Forward Scheduling” or complex optimization algorithms. It looks at the current moment (NOW) and begins placing work orders into the first available time slots on the required resources.

If Machine A is occupied with Order #101 until Tuesday at 2:00 PM, the system will not schedule Order #102 to start until 2:01 PM. It creates a realistic queue.

Finite-capacity scheduling is like a game of Tetris. The system takes the orders (blocks) and fits them into the available capacity (grid) without overlapping. If a slot is full, the block is moved to the next available opening. This means the system might tell you, “Based on current constraints, this order will be late.”

While this might be bad news, it is accurate news. It allows you to manage the customer’s expectations weeks in advance, rather than apologizing on the day of delivery.

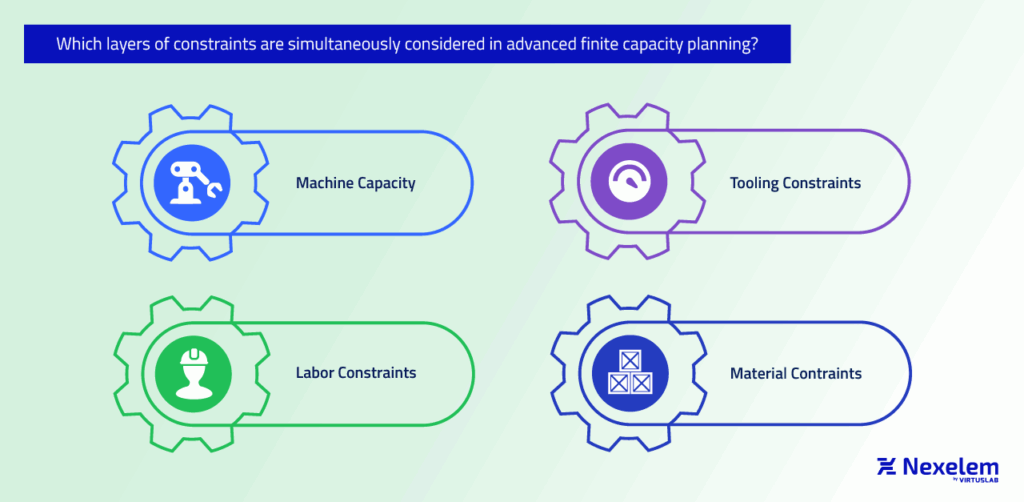

Resource Constraint Management: Beyond Just Machines

A common misconception is that capacity planning is only about machinery. However, true resource constraint management involves much more. A machine sitting idle because no one is running it is a capacity constraint.

Advanced finite capacity planning considers multiple layers of constraints simultaneously:

- Machine Capacity: Is the equipment running? (Considering maintenance and breakdowns).

- Labor Constraints: Do we have an operator with the required certification available to run this job?

- Tooling Constraints: We might have five injection molding machines, but only one mold for “Product X.” Therefore, we can run only one batch of “Product X” at a time, regardless of how many machines are available.

- Material Constraints: Is the raw material actually in the warehouse?

Ignoring any one of these constraints turns a finite schedule back into a wish list. This is why accurate data, specifically regarding OEE (Overall Equipment Effectiveness) and cycle times, is the fuel that powers finite scheduling.

Why Simple ERPs Struggle with Finite Scheduling

If finite planning is so much better for execution, why doesn’t every ERP use it? The answer lies in complexity and data.

Finite capacity planning requires a high-fidelity digital twin of your factory. If your ERP thinks a cycle takes 10 minutes, but it actually takes 12, the finite schedule will drift out of sync within a few shifts.

Most standard ERPs are transactional systems; they are great at recording what has happened (accounting, inventory deduction). They are often poor at simulating what will happen. When manufacturers try to force a transactional ERP to handle detailed finite scheduling, they usually resort to “Excel Hell”, exporting data to spreadsheets and manually dragging and dropping orders because the ERP’s logic is too rigid.

How Nexelem Bridges the Gap with APS

This is where APS (Advanced Planning and Scheduling) Software becomes critical. APS software sits on top of your ERP. It takes the orders and inventory data from the ERP/MRP and applies advanced finite scheduling logic to generate an executable plan.

Here is how Nexelem transforms the process:

1. Visualizing the Bottlenecks

Text-based lists hide problems. Nexelem’s Gantt Chart View visualizes each resource’s finite capacity. You can see the “white space” (availability) and the specific work blocks.

If a machine is overbooked, it doesn’t just show a red number; you can visually see the overlap. This allows planners to spot bottlenecks instantly. Visual management allows the human brain to solve spatial problems that spreadsheets obscure.

2. Optimization, Not Just Scheduling

Finite planning isn’t just about “first come, first served.” It’s about efficiency. Nexelem’s algorithms can sequence orders to minimize production costs.

For example, if you have five orders requiring “Black Paint” and three requiring “White Paint,” Nexelem can group the colors to minimize the changeover/wash-out time. This effective sequencing essentially “creates” capacity by reducing non-value-added setup time.

3. Handling the “What-If” Scenarios

What happens if a priority machine breaks down? In an infinite planning world, the schedule remains the same, and everyone just knows it’s wrong. In a finite world, that breakdown is a hard constraint.

Nexelem allows for dynamic rescheduling. You can mark a machine as “Down,” and the system will automatically look for alternative resources or push forward the dependent jobs. This predictive capability allows you to switch from reactive firefighting to proactive problem solving.

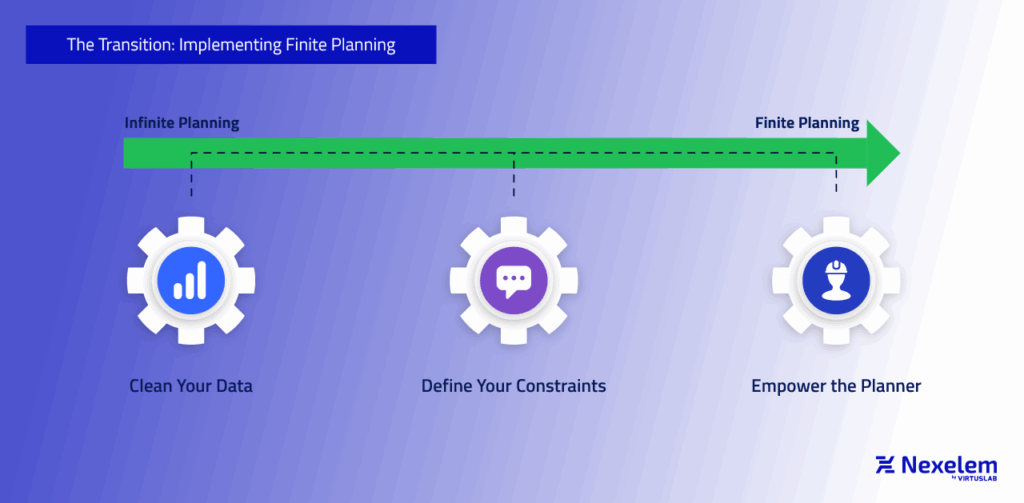

The Transition: Implementing Finite Planning

Moving from infinite to finite planning is a journey. It requires a shift in mindset.

- Step 1: Clean Your Data. You cannot plan if you don’t know your true cycle or setup times. (See how Lean Manufacturing principles help stabilize this data).

- Step 2: Define Your Constraints. Which resources are your actual bottlenecks? You don’t need to schedule every screwdriver in the end. Focus on the constraints that govern the factory’s flow.

- Step 3: Empower the Planner. Finite-scheduling tools like Nexelem handle the heavy computational work, while the planner makes strategic decisions. The tool provides the options; the human provides the context.

Conclusion: Which Approach Fits Your Factory?

So, back to the core question: Finite vs. infinite capacity planning, which do you need?

The reality is that a modern manufacturer needs both, but for different horizons.

- Use Infinite Planning for the long term (3-12 months out). Use it to budget, to plan workforce hiring, and to order long-lead materials via your MRP.

- Use Finite Planning for the short term (0-4 weeks out). Use it to tell the shop floor exactly what to do next, ensuring that the plan is feasible, optimized, and profitable.

Relying on infinite planning for daily execution is a recipe for high overtime costs, missed shipments, and burned-out employees. It places the scheduling burden on the shop floor supervisor, who lacks visibility to optimize the entire plant.

To stop guessing and start delivering, you must respect the limits of your reality. You need a system that understands that your capacity is finite, even if your ambition is not.

Ready to see a schedule you can actually trust? Explore how Nexelem’s APS Software utilizes finite capacity logic to maximize your factory’s output.