Value Stream Mapping – what is it and how to map the tool?

Value Stream Mapping (VSM) is a strategic Lean Management tool that allows manufacturing leaders to see the invisible: distinguishing between steps that add value for the customer and those that merely generate costs (waste). It provides a visual blueprint of the entire production flow—from raw materials to the final product. While traditional VSM requires time-consuming manual analysis, Nexelem changes the game. By using advanced MES software, companies can automatically generate dependency graphs that function as digital value stream maps.

Value Stream Mapping is one of the methods used in lean management. It is often described as a structured approach to understanding how value flows through an organization. Although developed by the global corporation Toyota, it can be used by any company. Both those currently experiencing operational problems and industry leaders are seeking to improve through value stream planning and systematic process optimization. What exactly is this tool? What are its advantages, and how can it be used? We encourage you to read on.

Table of Contents:

- What is Value Stream Mapping?

- History of Value Stream Mapping

- What is Value Stream Mapping used for, and what are its advantages?

- When is it worth performing Value Stream Mapping?

- Why is Value Stream Mapping worth using?

- How is Value Stream Mapping created?

- VSM step by step

- How to prepare Value Stream Mapping without a lot of effort?

What is Value Stream Mapping?

Value Stream Mapping is a method of graphically representing the components of processes (usually production-related). In simple terms, this explains what is meant by value stream mapping and why it is a core element of lean thinking. The goal is to analyze the steps taken to facilitate future changes. This tool allows you to gather a lot of key information, including:

- how the process is organized,

- what the added value is,

- whether there are sources of waste, and if so, what they are,

- what data flows into and out of the process,

- how long the process takes,

- what quantities of materials and raw materials are used,

- how many people are involved in each activity.

From a broader perspective, this stage already touches on what is value stream analysis, as it focuses on understanding both value-adding and non-value-adding activities.

History of Value Stream Mapping

Taiichi Ohno and Shigeo Shingo, who were employed by Toyota, are considered the originators of VSM. They developed this method in 1980 when they realized that by reducing the time between successive stages in the production process, they could improve productivity and reduce waste. This clearly defined the original purpose of value stream mapping, which was to shorten lead times and eliminate inefficiencies. However, the seeds of this approach had already been sown earlier, including at the beginning of the 20th century. Currently, it is used primarily for communication, strategic planning, and management style change.

The tool can also be used for ongoing process monitoring to quickly identify potential sources of risk that could soon turn into crises. In this context, VSM acts as one of the most practical value stream analysis tools available to managers.

What is Value Stream Mapping used for, and what are its advantages?

The use of Value Stream Mapping offers several practical benefits. The most important of these are:

- a graphical (and therefore easy to understand) representation of the connections within the process,

- providing a basis for developing an improvement plan that can be implemented to streamline the process. Through visualization and analysis, priorities can be identified and specific actions taken to achieve the desired results,

- value analysis, as VSM enables in-depth analysis of value flow, allowing the identification of steps that add value and those that do not,

- improvement of communication and cooperation, as VSM integrates different departments and teams within the organization, enabling better communication and understanding of the entire value stream. It thus acts as a common language tool that facilitates the identification and resolution of problems.

Thanks to these advantages, value stream mapping is widely recognized as a foundation for effective continuous improvement initiatives.

As can be clearly seen, VSM not only allows you to search, but also provides added value itself, and this at many different levels.

When is it worth performing Value Stream Mapping?

In fact, this method should be performed regularly to improve processes within the company continuously. This aligns closely with value stream planning, which assumes long-term and iterative improvement rather than one-off optimization. However, there are several cases when Value Stream Mapping is particularly worth applying.

One such case is when a company is unable to keep up with orders. Thanks to this analysis, areas where relatively quick improvements are possible, often without fundamental changes, can be quickly identified.

Another case is when an entity ceases to generate the expected income and generates excessive costs. Perhaps the process takes too long? Or are there inhibiting factors that negatively affect individual activities? Thanks to such an analysis, it is also possible to identify them relatively quickly and change processes so that the company is profitable again.

However, the above situations are considered critical. Therefore, Value Stream Mapping can serve as a preventive method, enabling the identification of areas that currently cause complications and may become even more detrimental to the company in the future.

Why is Value Stream Mapping worth using?

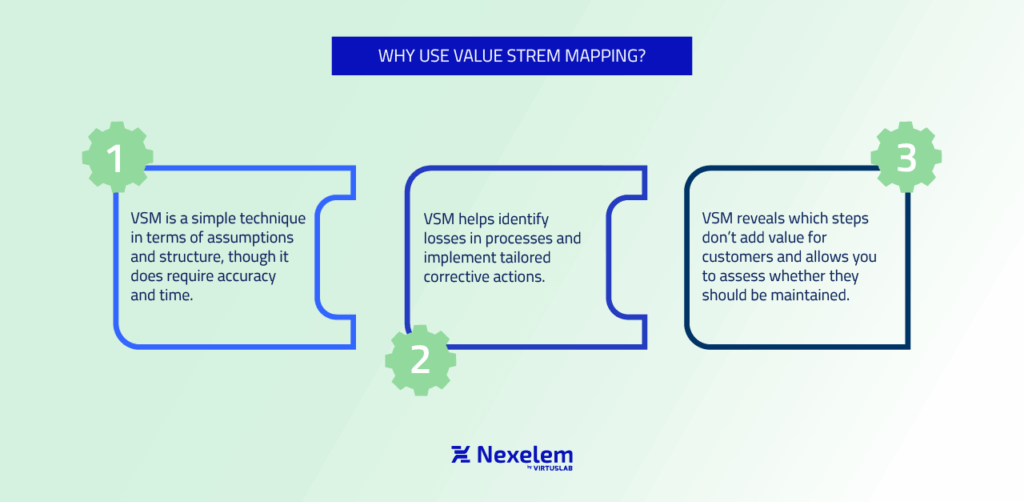

There are many reasons why this technique is so important and has become a permanent fixture in the canon of the most effective lean management methods.

Firstly, it is simple in terms of its assumptions and structure, although it obviously requires accuracy and time to capture all the relevant information about the process.

Secondly, it enables you to identify losses in processes and, based on this, implement tailor-made corrective measures. Its use, therefore, brings specific benefits.

Thirdly, it enables you to identify stages that do not add value to customers and assess whether they are worth retaining. This directly reflects what does value stream mapping mean in practice, which is focusing resources only where they truly matter.

In summary, Value Stream Mapping is useful. This is also because no expensive technological solutions are needed to carry out such an in-depth analysis.

How is Value Stream Mapping created?

Basically, the process consists of three stages:

- Analysis of the current state, i.e., Value Stream Analysis, without subjecting specific stages to deeper analysis. At this stage, a Gemba Walk is often carried out, i.e., a walk around the production plant to take a closer look at the individual stages.

- Creating a map of what the target state should be, i.e., Value Stream Design. This stage is when potential solutions are presented.

- Creating an action plan, i.e., Value Stream Work Plan. This is the time for selection, i.e., choosing the best and most feasible solutions.

These phases correspond directly to the core steps in value stream mapping described in lean management literature.

The process does not end with possible implementations. It is worth repeating VSM regularly because, according to lean management, the improvement process never ends, and there are always elements that may need improvement.

The process does not end with possible implementations. It is worth repeating VSM regularly because, according to lean management, the improvement process never ends, and there are always elements that may need improvement.

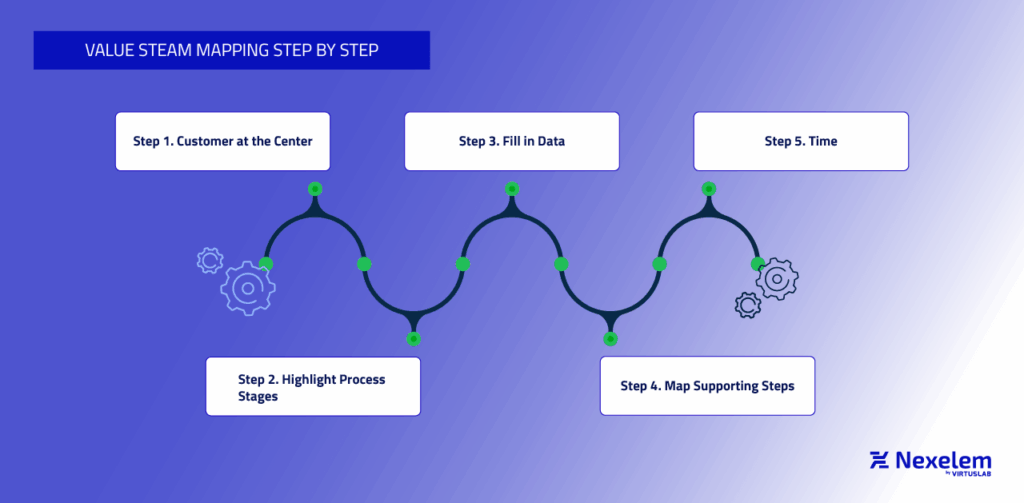

VSM step by step

We have the assumptions and theoretical knowledge, so now it’s time to get down to specifics, i.e., what Value Stream Mapping should contain. Here are the rules for creating such a map, which together form the practical steps in value stream mapping.

Step 1. The customer is at the center of events.

In practice, the customer is at the center of events in VSM. Therefore, it is best to place their symbol in the upper corner of the sheet, along with a description of their product requirements.

Step 2. Highlighting the stages in the process.

We list the individual stages in our process, which will, of course, vary depending on the company.

Step 3. Fill in the data.

Under each stage (segment), we fill in information such as:

- the number of employees required to perform the activity,

- the time cycle,

- RFT (Right First Time), i.e., how many cases, in percentage terms, proceed without problems and move on to the next stage,

- Batch size, i.e., the size of the batch,

- Up Time, which is the percentage of time when an employee or machine is productive, and this time is, of course, recorded without breaks.

Step 4. Mapping side steps.

Very often, this is where the sources of costs and problems lie, i.e., those elements that delay the process. These are the so-called exploding stars, which are best captured on the map so that they stand out clearly.

Step 5. Time

The next step is to indicate the timeline for the process, i.e., how long the activities take and what the downtime between them is.

Of course, mapping may vary depending on the industry in which the company operates and the specifics of its activities. You can also add other elements to it and improve it.

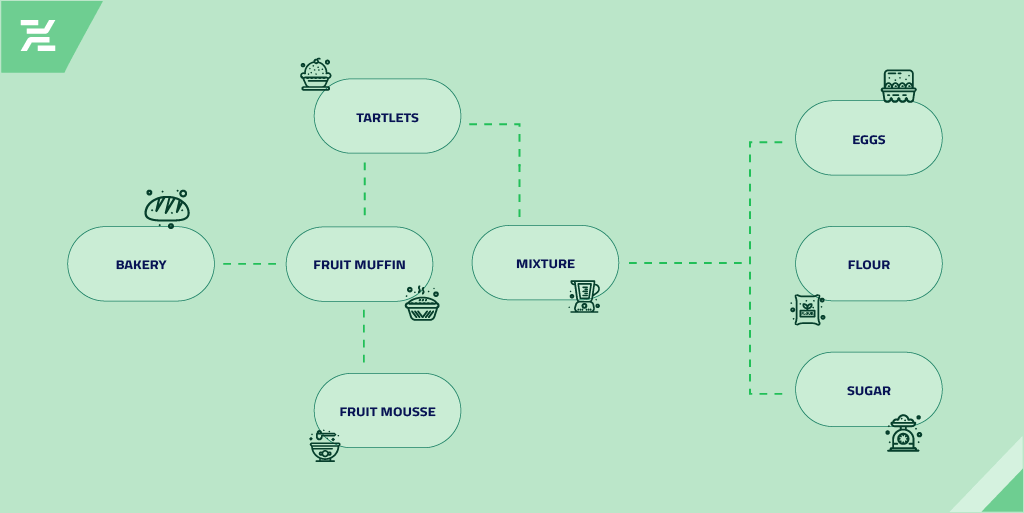

How to prepare Value Stream Mapping without a lot of effort?

Performing VSM requires time, patience, and accuracy. What should we do when we lack resources or when the company’s processes are highly complex?

Modern technologies can help with this. An example is our MES production management software, one of whose features is the so-called dependency graph (which can be considered a visualization of VSM). Such systems effectively function as a value stream mapping program, automating data collection and analysis. These dependencies can be mapped not only for large manufacturing companies, but also for smaller entities, where such analysis will be faster and easier.

When deciding on MES software, the company has at its disposal not only the Value Stream Mapping program, but also other information that allows it to make processes more efficient. These include:

- the ability to plan multi-stage production,

- predefined recipes,

- monitoring of production slot utilization,

- generation of orders for internal transport of raw materials,

- monitoring of employee performance,

- tracking of production process profitability,

- easy, fast, and accurate reporting.

Value Stream Mapping is a method that is still underutilized in the Polish economy. However, as you can see, it has several principles and can help solve the most significant problems of a company related to production processes in a relatively short time.

F.A.Q. about Value Stream Mapping

About Nexelem

Nexelem is a flexible, modular system that streamlines production management and optimizes operations. It was developed by VirtusLab Ltd., a company supporting global manufacturers since 2010. VirtusLab employs over 400 IT specialists who build software and digital tools focused on helping production companies achieve more, using fewer resources, with a lower environmental impact.

Discover how our solution works in your environment.

These phases correspond directly to the core steps in value stream mapping described in lean management literature.