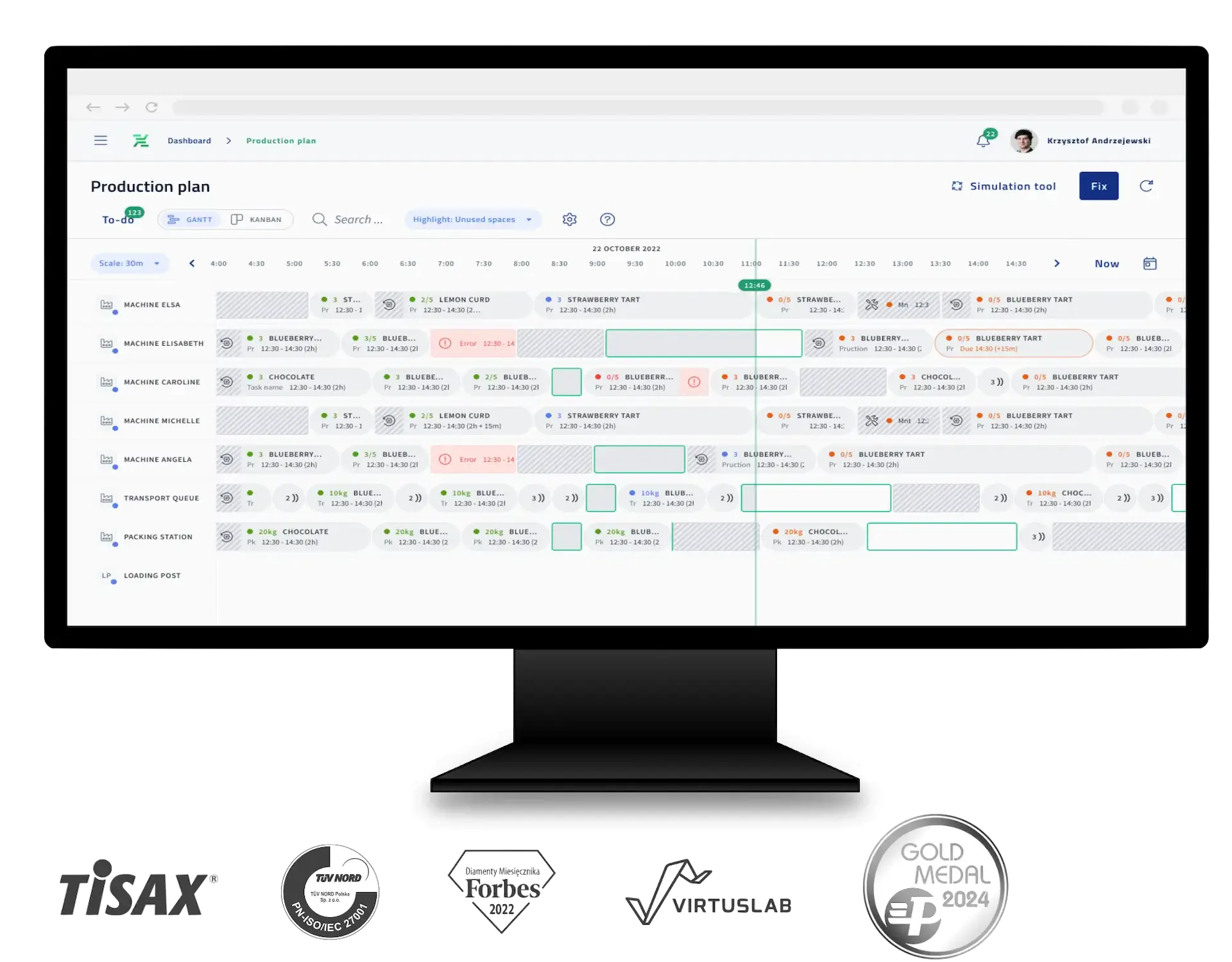

Advanced Planning and Scheduling Software

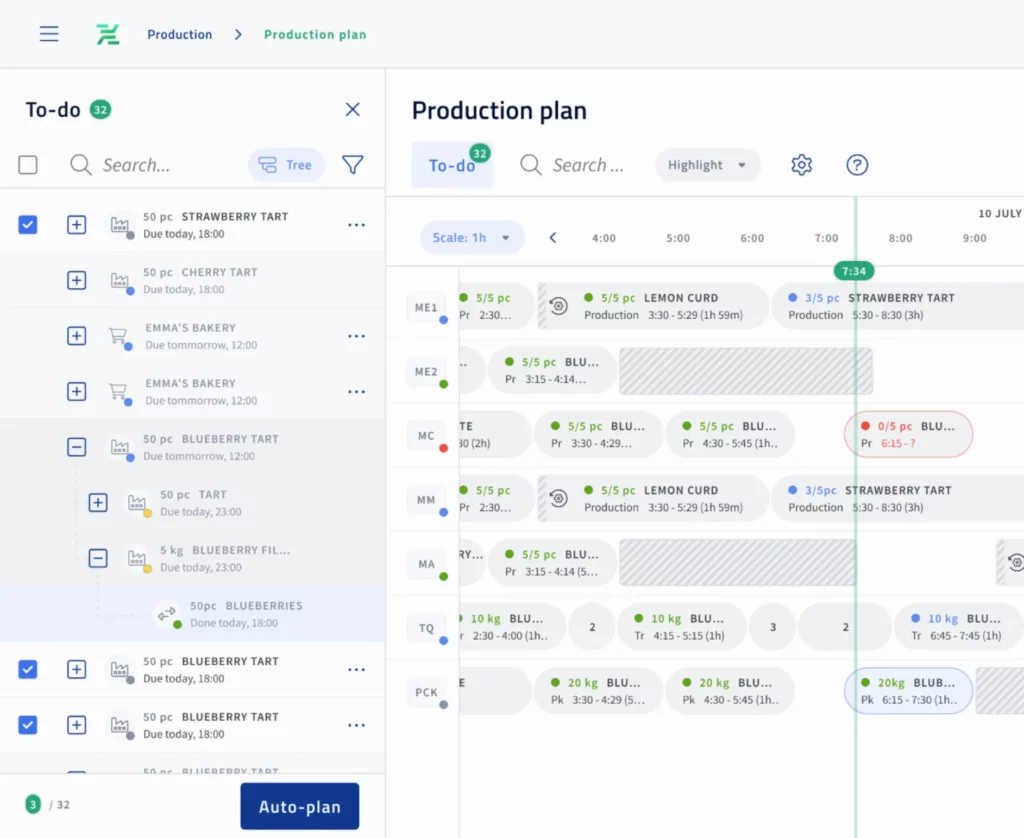

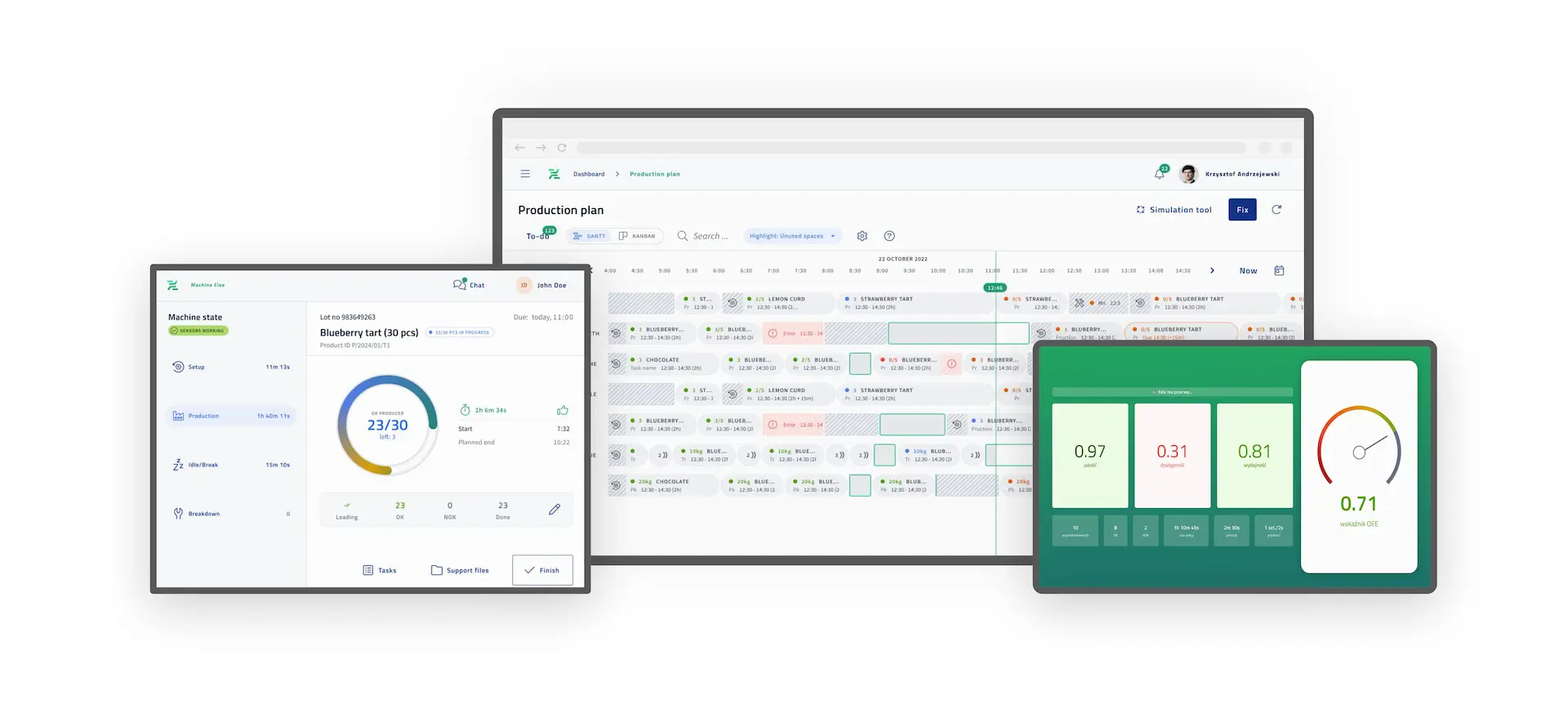

The ultimate Production Planning and Scheduling Software to optimise the Production Queue intelligently.

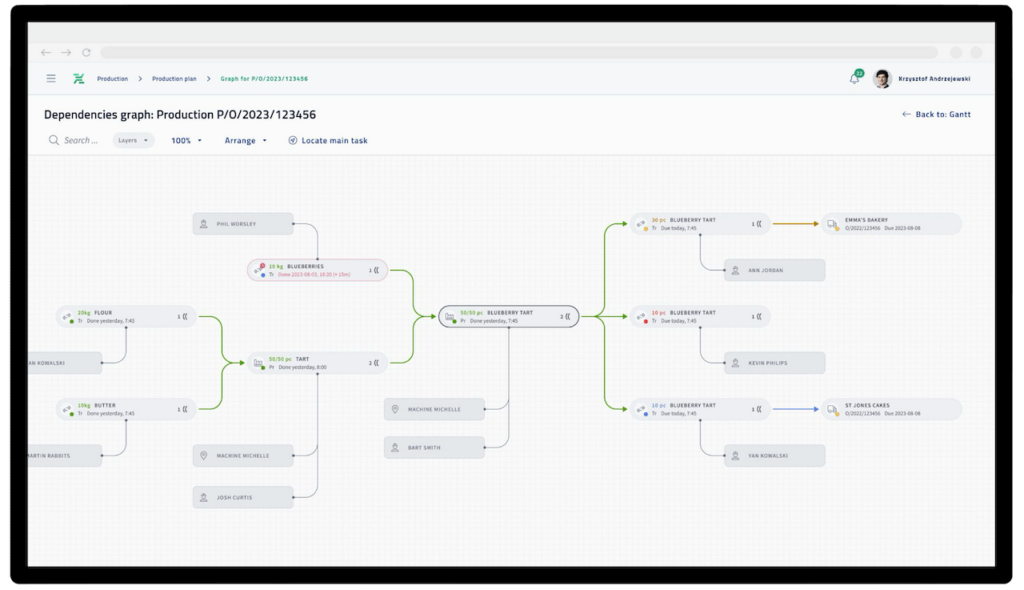

Take advantage of APS software and optimally allocate materials to fit capacity in your complex production processes.

- Custom implementation based on innovative advanced planning and scheduling algorithm

- Integration with your existing solutions and machines.

- Cost effective and easy to use for non-technical people.