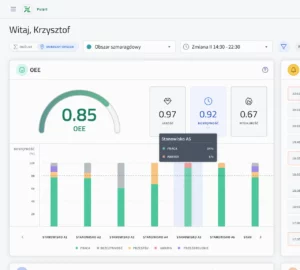

OEE Monitoring Software for Machine Analytics & Downtime Tracking

OEE tracking and machine monitoring are powerful tools to boost efficiency on the shop floor. By tracking availability, performance, and quality in real time, OEE Monitoring gives a clear picture of how well machines and production lines are truly running. It helps identify bottlenecks, reduce downtime, and eliminate waste – leading directly to higher productivity and lower costs. For any smart factory striving for continuous improvement, OEE Monitoring is essential to achieving world-class manufacturing performance.